AZURE-L

Lead Dissolver

Nuclear Shielding Decontamination and Recycling

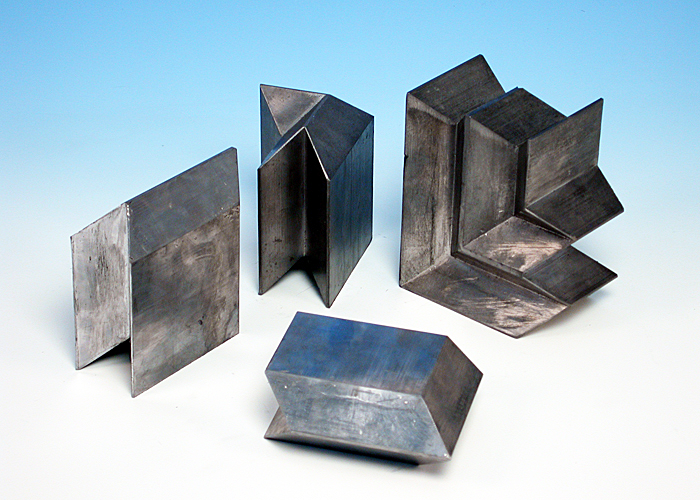

Lead bricks used in the nuclear industry for shielding become contaminated by radioactive materials, due to activation as a result of neutron bombardment of metals, such as Antimony present in the lead alloy bricks to improve their physical qualities.

Bluesky have developed a new method which allows the decontamination and recycling of the lead. A new patented formulation specifically dissolves the lead, leaving radioactive metal components as a waste sludge that can be isolated for disposal. The solution containing dissolved stable lead (Pb-206) can be redeposited and recycled for the manufacture of new products thereby avoiding the need for long-term storage of large quantities of radioactive waste in underground repositories. Patent GB2218581.3.

Decontamination of Lead-210 contaminated Oilfield Equipment

Decontamination of Radioactive Lead-210 contaminated oilfield equipment can also be rapidly achieved using AZURE-L. Oilfield reservoir formation waters can contain Lead-210 radioisotopes that plate onto steel surfaces and render equipment radioactive. This was formerly a particular problem for valuable downhole tools because ultra-high pressure water jetting is often ineffective in removing Lead-210 particles that enter the steel’s surface and they required destructive grit blasting to decontaminate them. AZURE-L can now completely decontaminate tools by a simple soak for about an hour.

A gas compressor contaminated with Pb-210 could not be cleaned by conventional means. Bluesky technology was utilised at the nuclear facility at NRG in the Netherlands to completely decontaminate the compressor by filling the compressor with lead dissolver.