AZURE-XPM

Mercuric Sulphide Dissolver

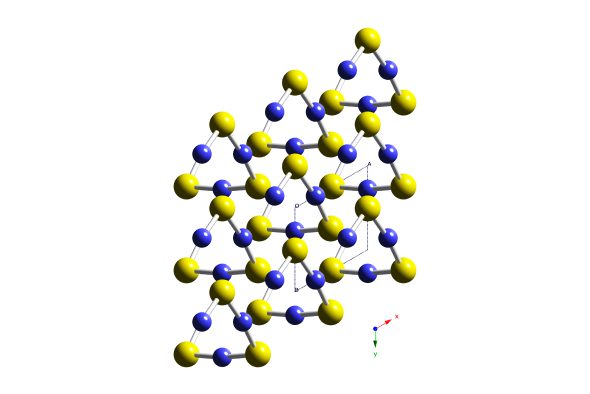

Mercury sulphide mineral scale can form in oilfield processing vessels and pipes, storage tanks on FSOs and subsea pipelines. The sulphide can react with volatile mercury vapour to form mercury sulphide mineral scale which adheres to the walls of vessels and pipes. The patented alkaline dissolver AZURE-XPM was specially formulated to remove mercury sulphide rapidly at ambient temperature. AZURE-XPM has applications in decontaminating oilfield equipment, decommissioning FSOs and decontaminating subsea pipelines to prevent toxic mercury entering the sea following decommissioning.

AZURE-XPM has been shown to be equally effective at dissolving Mercuric sulphide when applied to tank walls as a spray thereby allowing very large storage tanks to be decontaminated with a small volume of dissolver.

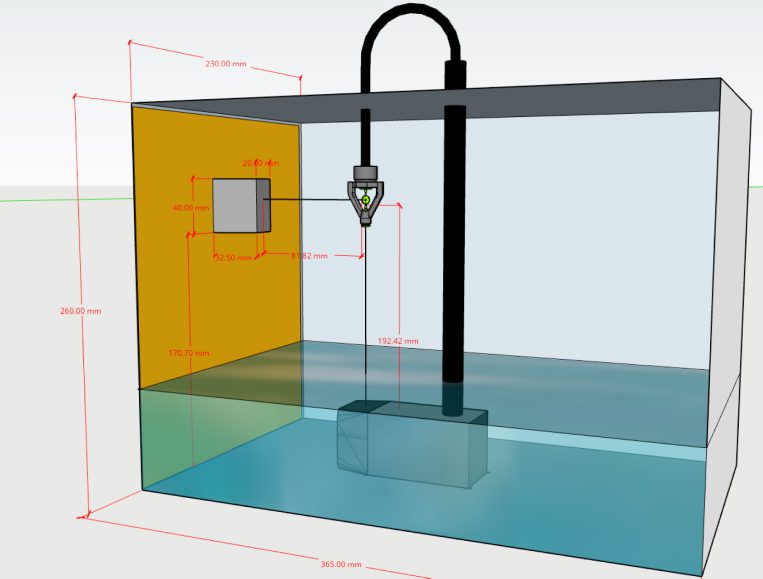

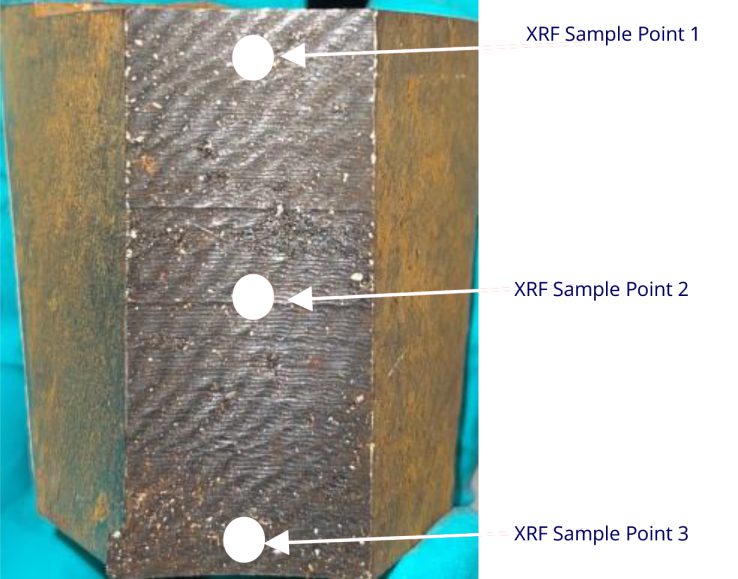

Experimental set up for the testing of Mercuric Sulphide decontamination by AZURE-XPM applied as a fine spray (left credit Blake Wheeler Enermech Australia) onto a field HgS-contaminated coupon (right).

A glass aquarium, submersible pump and rotating nozzle were used to spray AZURE-XPM onto a wall- mounted mercuric sulphide contaminated steel coupon. The coupon was cleaned to below the X-ray Fluorescence (XRF) analyser’s mercury detection limit within 2 hours of very light spraying at 25C.

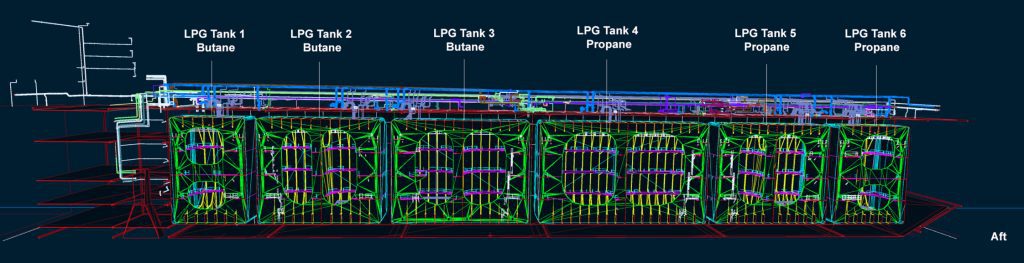

The storage tanks in Floating Storing Offloading (FSO) supertankers and associated piping can become contaminated with mercuric sulphide and elemental mercury. When the vessels are decommissioned the steel tanks need to be decontaminated to allow the steel to be recycled.

AZURE-XPM can decontaminate the walls of tanks by simply spraying the dissolver onto the steel walls using a rotating nozzle fitted on a robotic arm. When toxic elemental mercury is also present, AZURE-M can be applied to dissolve it.